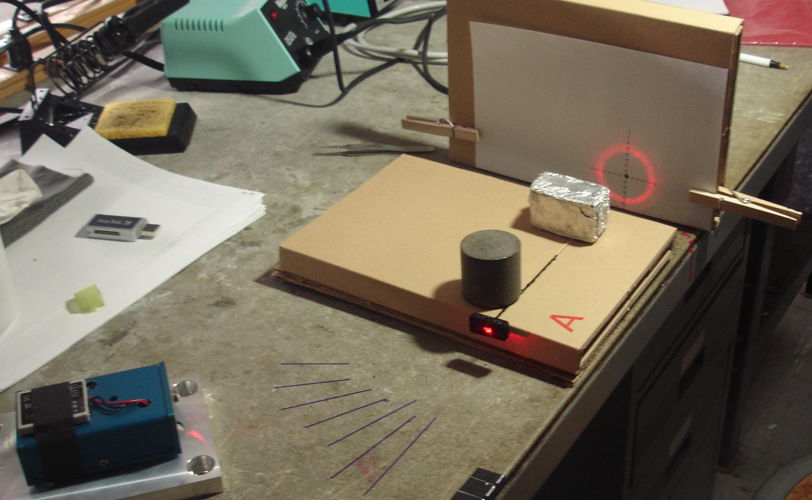

We cut a 200-mm length and cover it with black epoxy of refractive index 1.5 for half of its length. We polish both ends with diamond grit paper to give an optical finish. The epoxy makes sure no light gets into the rod through its curved surfaces. It mimics the epoxy we have been using to bind our fiber to our LED, and makes sure that the cladding of the rod is what causes total internal reflection in the core, rather than the cladding-air interface. We set up the cladded rod as shown below, with a 650-nm red laser beam shining into one end, and a screen to observe the pattern of light emitted by the far end. We place a black foam baffle around the near end of the rod.

The light entering the rod emerges in a cone, making a ring on our screen. When a light ray enters a cylindrical rod at an angle θ to the axis, reflections off the rod surface re-direct the ray, but do not change the angle it makes with the axis. When the ray emerges from the rod, after many reflections of a perfectly-cylindrical rod, it emerges at an angle θ to the axis. We see two cones for small angles of incidence, but in the photograph we are at 40° and the ring is clear and sharp. With a photodiode and our graduated screen, we measure the power emerging from the end of the rod and the angle of the cone it emits. We obtain the following graphs.

Our measurement of transmission becomes unreliable for angles bigger than 60° because the rod end presents such a small area to the laser beam. Nevertheless, we see that the rod captures and transports more than 50% of the light incident upon one end for angles 60° and lower. With numerical aperture 0.61, we expect to get total internal reflection within the rod for angles less than 38°. We see 80% transmission at 40° and 25% at 60°. We believe these results are consistent with numerical aperture 0.61.

If we could obtain such a rod with diameter 400 μm, its numerical aperture for blue light would be 0.66. With such a fiber we could capture 43% of light emitted by our LED and transport it to the fiber tip. If we coat this rod with a layer of adhesive with index 1.32, the coated rod will have numerical aperture 0.96. It will capture and transport almost all the light that enters its base from our LED.

UPDATE: [27-MAR-13] Fiberoptics Technology tells us they can make 400-μm clad rod of the same type studied here. We have ordered a batch to arrive in a few weeks. The company tells us that they believe they can make the same diameter clad rod out of glass with index 1.75. When combined with their cladding, a core of index 1.75 provides numerical aperture 0.92, with no need to use low refractive index adhesives.

UPDATE: [15-APR-13] We try out a Luxeon Z LED, the blue LXZ1-PB01 version. The LED emits roughly 29 mW for 30 mA forward current. The emitting surface of the LED is 1.2 mm square. We place our 1.2-mm diameter, 200-mm long clad rod over it and observe roughly 40% of the power emerging from the other end. The rod covers 80% of the emitting surface of the LED, so it appears that the rod is transporting 50% of the light that enters its base.

UPDATE: [16-APR-13] We receive several hundred meters of clad rod from Fiberoptics Technology. Its diameter is 390 μm. We can bend it with into a radius of 10 cm. We take a 20-cm length, polish both ends, and glue one end to our LXZ1-PB01 blue LED. We use UV-curing adhesive of refractive index 1.54. We coat most of the length of the rod in the same adhesive. We run 30 mA through the LED, so that it emits 29 mW. The rod covers 8.3% of the emitting area of the LED, so we expect 2.4 mW to enter the base of the rod. If the numerical aperture of the clad rod is 0.66, we expect 44% of the light to reach the other end, or 1.0 mW. We measure 1.4 mW at the other end. We press the rod tip against a piece of white paper so we can see the cone of light it emits. The angle at the base of the cone is roughly 74°, which suggests a numerical aperture of 0.60.

No comments:

Post a Comment