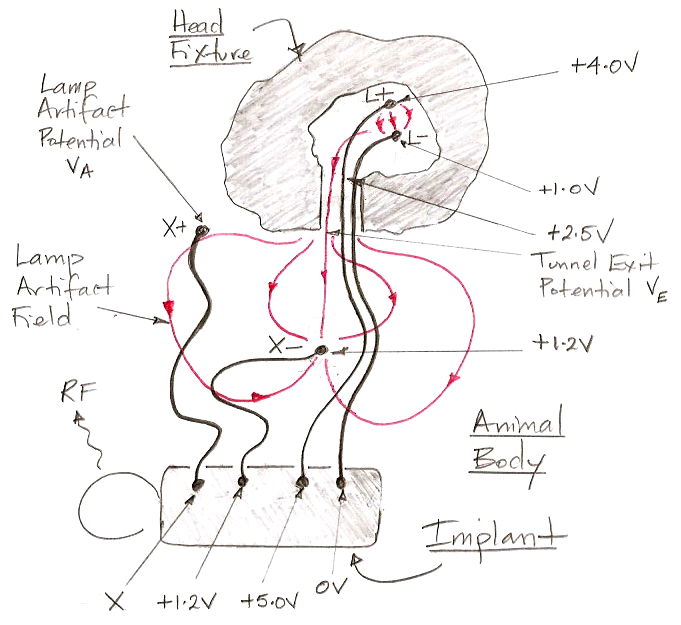

Figure: Lamp Artifact Current Flowing From L+ to X− When Lamp Is On. Voltages with respect to the implanted A3030D's 0V supply. Head fixture made of dental cement. Current in the leads is not shown.

We later tried the A3030D-LO, lamp-only version, with a Subcutaneous Transmitter A3028E to monitor EEG. We saw no lamp artifact in the EEG we recorded, as the following diagram attempts to explain.

Figure: Separate SCT for EEG, ISL without EEG for Lamp. Head fixture made of dental cement.

One way to restore the ISL's own EEG measurement is to insulate the lamp leads with a ceramic collar, as we describe here. The ceramic collar makes is hard to explant and re-use an ISL because the solvent used to dissolve dental cement will also attack the adhesive we use to bind the silicone to the ceramic. The ceramic collar is arduous to assemble, and makes implantation of the head fixture more difficult. Furthermore, although we have tested the ceramic collar for fatigue resistance with machines and water here in our laboratory, we remain uncertain as to its reliability during a two-month experiment.

We propose to eliminate the ceramic collar. Instead of blocking the lamp current, we will absorb it with a coil of wire that enters the head fixture and wraps around the lamp leads. We will use a stainless steel compression spring for the purpose. For EEG detection we will use a differential amplifier in the A3030E rather than a single-ended amplifier. The current flow in the head fixture and animal we expect to be as shown below.

Figure: Grounded Seal Arrangement. Head fixture made of dental cement.

Our initial tests of this arrangement are promising. We await the arrival of the A3030E circuits, when we will be able to test the arrangement with a differential amplifier built into the ISL.

UPDATE: Here is a prototype grounding arrangement. A stainless steel spring is coiled around two lamp leads.

Figure: Grounding Spring Coiled Around Two Leads.

We can slide the spring up and down the lamp leads, but the lamp leads are pressing outwards against the coils. If the spring protrudes from the head fixture a few millimeters, it will provide a grounding point for our EEG measurement. Because it is wrapped around the lamp leads in the tunnel they make through the head fixture cement, the spring will absorb all lamp current that might flow through the tunnel.