We became interested in designing a tethered system for delivering optical power to head fixtures. The possible advantages of a tethered system include indefinite experiment life, high light output, and low cost. This post assesses one way to make such a system and then proposes an alternative method.

Concept

We plan to couple light into the optic tether by directly pressing the proximal end of the fiber against the surface of a bare LED, as we do with the

ISL. The distal end of this optic tether will then be coupled to a short fiber taper that is implanted into the test subject's brain.

Our chief goal is to deliver a sufficient amount of light from the LED to implanted fiber tip. We could use the T5 glass used in the ISL, which has exceptionally high numerical aperture, but its

high absorption makes it much better suited for short tapers than long patch cables. We've found that it is better to use glass with lower numerical aperture, but superior transmission; therefore we decide to use our "

high index fiber" rather than "

higher index fiber".

In direct coupling, optical power capture is proportional to the area of contact between LED and fiber. As we are interested in capturing about 30mW, we want to use a fiber with diameter over 400um. However, single fibers this large are not flexible enough for use as tethers in experiments. We contacted

Fiber Optic Technologies and purchased several fiber bundles from them. Each bundle contains about 73 fibers glued to one another, each with 50um diameter. The numerical aperture of each strand is 0.66. The total bundle diameter is 500um, and the bundle is one meter long. The bundles we've purchased are packaged as patch cables; they are 1m long, coated in silicone, and each end is terminated in stainless steel ferrules. Being very flexible, these patch cables are physically suited for a tethered experiment.

We plan to connect one end of the patch cable to the LED, and connect the distal end to a head fixture with its own implanted fiber. The T5 tapers currently used in the ISL are a good choice for the implanted fiber since for distances less than 1cm, absorption losses are small. Since T5 has excellent numerical aperture, it should capture a large amount of light from the patch cable, and we have perfected the process of

tapering this kind of glass to a sharp point.

We initially planned to use Cree's

C460EZ500. Unfortunately, the bond wire of the EZ500 is pressed by the stainless steel ferrule of our patch cables, potentially causing a short. We could avoid this in the future with different ferrule choice, but for now, we continue our experiment with the blue

Luxeon Z LED. The die of the Luxeon Z is a square, about 1mm on each side. Our sample is the blue version, 470nm. Optical power isn't specified for the 470nm die, but the manufacturer specifies 1050mW for the top bin 447.5nm version at its maximum rated continuous current, 1000mA.

For coupling efficiency from LED to fiber bundle, we expect the following losses:

500um diameter fiber bundle over 1mm x 1mm square die: 80.4%

10% gaps between individual fibers: 10%

13% of each fiber occupied by cladding: 13%

Numerical aperture of 0.66 limits the angle of the acceptance cone: 56%

We expect the amount of light to be captured by the fiber bundle to be 6.8% that emitted by the LED.

The next step in the tethered system is to couple this light into the T5 taper. Because the T5's numerical aperture is larger than that of the bundle, we expect all angles of rays to be captured. However, there is a mismatch in refractive index that will cause reflection. Examining the data sheets for

F2 glass (used as the core of our patch cable) and

P-SF69 (similar to the proprietary T5 glass in the core of our implantable tapers), we see that their refractive indices at 480nm are 1.6331 and 1.74158 respectively. This means that perpendicular rays will be subjected to 3.21% loss. At other angles, the reflection coefficient increases or decreases slightly depending on the ray's polarization. In this case, 3.2% is a good estimate for total reflection loss.

A larger loss will be incurred by the mismatch in diameters: the core of the T5 fiber that we intend to use is 420um, versus the 500um diameter of the bundle. This introduces a loss of 29.5%. The final form of loss is absorption, which we have measured to be 2.2% along a 10mm length. We expect 66.7% coupling efficiency from the bundle to T5 fiber. In total, we hope for 4.5% of the LED's light to emerge from the implanted fiber.

Experiment

We test our calculations by measuring optical power using an SD445, as described

here. To avoid overheating the LED, we pulse it indefinitely for 1ms on and 19ms off. We observe a cleanly square signal of both the current passing through the LED and of the optical power produced, indicating that the LED is functioning normally and not being overheated. We drive the LED at its maximum continuous current rating, 1amp.

We measure 513mW optical power from the LED. Using a 3-D micrometer stage, we position the fiber bundle directly against the die in the position that gives maximum transmission. Power at the distal end of the fiber bundle is 41.5mW. 8.1% of the LED's light is coupled into the fiber, greater than the 6.8% we expected.

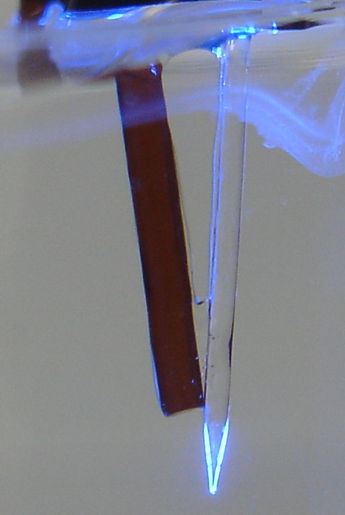

Next, we use a second micrometer stage to align a 141mm length of T5 glass against the distal end of the fiber bundle. The outer diameter of the T5 fiber was measured to be 0.45mm. We estimate its core diameter to be 420um. Both ends of the fiber bundle as well as both ends of the T5 glass are highly polished. We measure 17.6mW output from the distal end of the T5 section. From our knowledge of attenuation in T5 glass, we expect that 27% of the light initially captured by our 141mm section is lost due to absorption. In that case, the power initially captured in the T5 section is 24mW. The amount transmitted 10mm from the junction is 23.5mW. This is the figure we are interested in. Transmission from the bundle tip to 10mm down the T5 glass is then 23.5mW/41.5mW = 56.6%, lower than our anticipated 66.7% estimate. At this point along the T5 fiber, 4.6% of the light produced by the LED is present.

Fill Factor Estimation

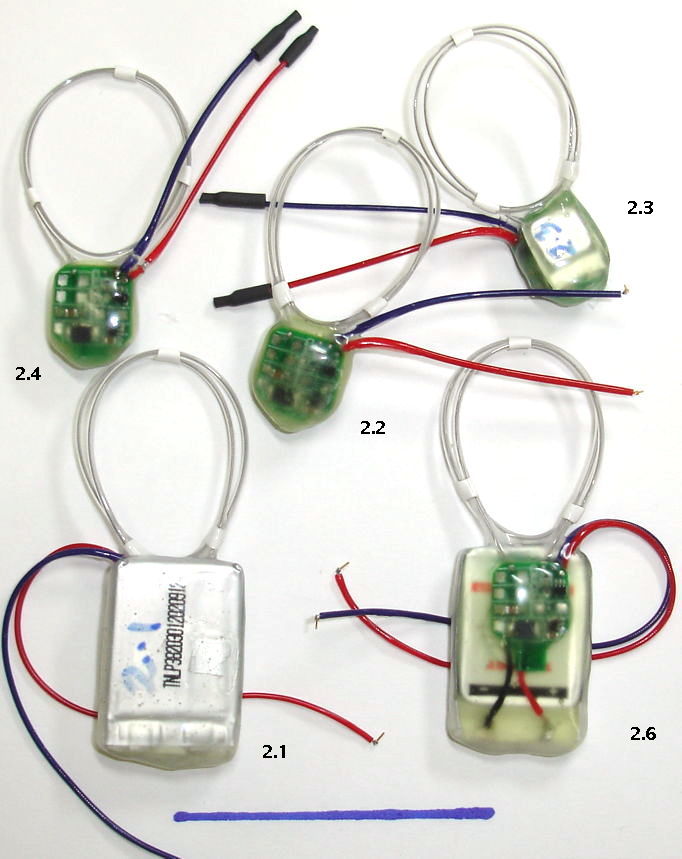

We took photographs of the end of the patch cable with our microscope. The other end of the patch cable is being illuminated by the LED at low power so that we can visualize the optically active region of the bundle. This photo tells us that there are 73 functional fibers in the bundle.

Figure: Original photo of fiber bundle being illuminated by LED

There are multiple ways to estimate the percent of the fiber bundle's area which is occupied by core glass. We call this percentage the bundle's "fill factor". First, we can simply assume the nominal dimensions are correct. If the core of each strand is 50um and the total diameter is 500um, the fill factor is 73%.

Next, we could analyze the image directly using software. We convert the image to black and white using a thresholding operation, and count the white pixels to obtain a measurement of core glass area. We then measure the diameter of the bundle in pixels and calculate its total area. This method is sensitive to our arbitrarily selected threshold. Depending on threshold, we estimate fill factors between 57% and 69%.

Figure: The image is converted to black and white to count optically active regions of the bundle. The arbitrary selected threshold affects our estimate of fill factor. The two ends of the reasonable range of threshold values give 57% and 69% fill factors (left and right respectively).

Consider that the core diameter of T5 used in our experiment was 420um. If the fill factor of the bundle is 65%, then the power carried by the inner 420um of the bundle could have been replaced by a single strand with core diameter 340um. A single fiber of this diameter would likely be too stiff for experiments, so the bundle does represent an advantage over an optically equivalent single strand in this regard.

One way to improve light capture is to improve the fill factor. Glancing at the image, it appears possible to fit more individual strands into the same diameter bundle, though we don't know how difficult it would be for our supplier to accomplish this.

Alternate Methods

In the course of our experiment, we found that the Luxeon Z could be over-driven without apparent damage. For a current of 1.3A and 1ms pulses, the LED produced 17% more light than at 1A. Operating in this mode would produce 27.5mW at the implanted fiber's tip, but long term effects on the LED are unknown, and accidentally leaving it on continuously at the high current would likely damage it.

There may be a better way to make tethered LED hardware altogether. Plexon advertises LED units on

their website. They advertise 24.9mW for their blue LED (465nm) at the end of a 1m long, 200um core fiber, NA= 0.66. They indicate that this power can be sustained continuously and can be increased for low duty cycles (over driving the LED). This is a large amount of light for such a small fiber. Unless Plexon uses LEDs with much higher luminous density than any that we're aware of, we don't believe this kind of result is possible with direct coupling. Perhaps their system uses a lens to focus the LED's light to achieve this impressive result. In the past, we'd discounted this option, since it is impossible to focus a Lambertian source to a point smaller than itself with simple lenses. Perhaps this isn't necessary, however. One could design a focusing system with the admission that only rays sufficiently parallel to the diode will be captured. For a large LED such as the Luxeon Z, this might work well. The wide angle rays from the LED may be lost, but we'd be able to capture all sufficiently parallel rays from its large 1mm square surface. These rays could be focused into a spot small enough to couple light into a 200um core fiber as Plexon may have done. Through our alignment projects in physics experiments, we have experience aligning laser diodes with lenses to focus light into fibers. Our system could be adapted to work with LEDs. Note that a 200um core single strand would be suitably flexible for experiments, making the bundled approach unnecessary.

Plexon's published results also tell us something about the efficiency of transmitting light from one multimode fiber to another. In our experiment, we observed 57% efficiency in coupling from the fiber bundle into the T5 fiber when we expected 67%. This indicates a 15% unexplained loss. This unexplained extra loss may be the result of the geometry of the fibers within the bundle (perhaps the local fill factor - directly beneath the T5 fiber's core - was smaller than the total fill factor). However, it seems more likely that it is due to an effect that we haven't yet identified, such as extra reflections.

Plexon may also be experiencing this mysterious loss; of 24.9mW at the end of a patch cable, they couple 19.9mW into a fiber stub of the same diameter (and presumably same fiber). In our model, the transmission efficiency between identical fibers is 100%, so their 20% loss is surprising. This loss at the fiber-to-fiber junction mirrors the loss we observe in our experiment, and could be due to the same source, (extra reflections?). In future work, we should keep the possibility of 15-20% fiber-to-fiber loss in mind.

Conclusion

With the blue Phillips Luxeon Z LED mounted on a heat sink, a 1-m flexible fiber-optic bundle, and a 10-mm implant fiber, we can deliver 23.5 mW continuously to the brain of an animal.