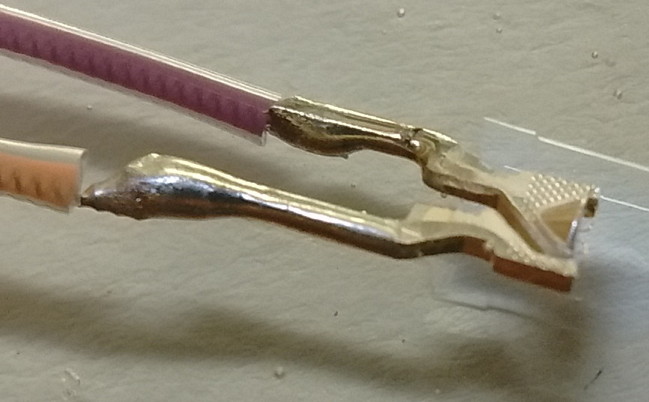

Figure: Corrosion of Negative Lamp Joint after Three Days In Water.

The charging diodes D4 and D3 CMDSH2-3 are reverse-biased, but they are Schottky diodes chosen for their low forward voltage during charging, and their reverse leakage current is of order 2 μA. This current flows out of the L− lead. Hydroxide ions in the water give up an electron to carry the current, resulting in a metal oxide and half a hydrogen gas molecule. The stainless steel springs do not corrode, even though we expect iron to corrode preferentially to copper during voltage=driven corrosion.

Figure: Recharging Diodes. Diodes D3 and D4 conduct during charging. Their reverse leakage current flows between the lamp pins through water when the device is inactive.

We encapsulate two lamp leads with an LED in clear epoxy. We attach the lamp to E157.3. We cover with 1.2% saltwater and pull with 1 N force on the leads 200 times. The next day, we pull 10 more times. We can see a water film around the lamp leads where they pass through the epoxy. We observe lamp artifact of 800 μVpp when we place the EEG leads in the saltwater without the grounding spring and 40 μVpp with the grounding spring. The figure below shows the LED leads and solder joints after one day and ten days.

>Figure: Lamp Encapsulated in Clear Epoxy, Immersed in Saltwater. Top: Day One. Bottom: Day Ten. Note the clear epoxy dome of the LED is almost invisible now that it is immersed in a larger body of clear epoxy.

After fourteen days, we pull the purple and orange wires out of our epoxy fixture. The purple wire snaps where we scratched it to remove insulation. The orange wire breaks at the edge of the solder joint. We remove silicone from the end of the purple lead and examine the steel. The surface is untarnished.

A better choice of diode would be one with far lower leakage current, such as a PN-junction small-signal diode. We connect the cathode of a 1N4448 to +3V, a wire to the anode, and a wire to 0V. We put the far ends of the wires in water. The anode wire models the L− wire in the A3030E, but the 1N4448 reverse leakage current is of order 20 nA. After two weeks, we see no corrosion on the wires.

The corrosion caused by the 2-μA leakage current of the CMDSH2-3 does not spread to the stainless steel of the leads and is suppressed cement on the surface of the copper parts. In future versions of the ISL, however, we will use low-leakage silicone diodes in the battery recharge circuit so as to avoid electrically-induced corrosion altogether.